Major processes in biochar based fertilizer making

What is the step to make biochar-based fertilizer?

The major process in biochar-based fertilizer making include composting, crushing, granulating, packaging etc. Certainly, if you have a powdery production line, you don’t need granulating process.

Pick up raw materials

The first step of process in biochar-based fertilizer making is choose raw materials. You must make sure these raw materials come from the merchants you can trust. And these raw materials must fresh and healthy. Some common ingredients include rice husk, corn stems, peanut shells, etc.

Composting the raw materials

The second step of process in biochar-based fertilizer making is composting. Composting should be carried out under aerated conditions. Firstly, the raw materials of charcoal-based fertilizer are piled up and fermented, generating a lot of heat, and the temperature inside the heap is as high as 50-60°C, thus rotting fast, and the nutrient content is high. The high temperature fermentation process kills the bacteria, insect eggs and weed seeds in the pile. So, if you want to compost, you can choose our groove type compost machine.

Why you need a compos turner machine?

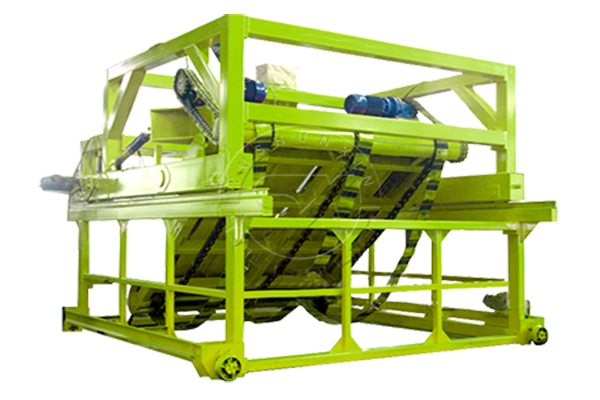

However, if composting is done by manually, it is not only slow but also prone to too low or too high temperatures. This will not kill the harmful substances, or the organic matter will also be eliminated. So I recommend that you can consider the compost turner machine of our company. Use of our company’s compost turner machine, it can saves time and efficiency, and also saves labour and improves economic efficiency.

For example, our groove type compost turner is not only cheap, but also efficient. And it has a turning span of 3 to 30 meters and a depth of 0.8 to 1.8 meters.