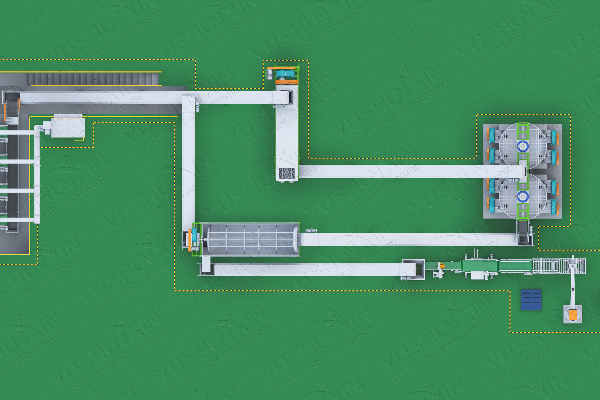

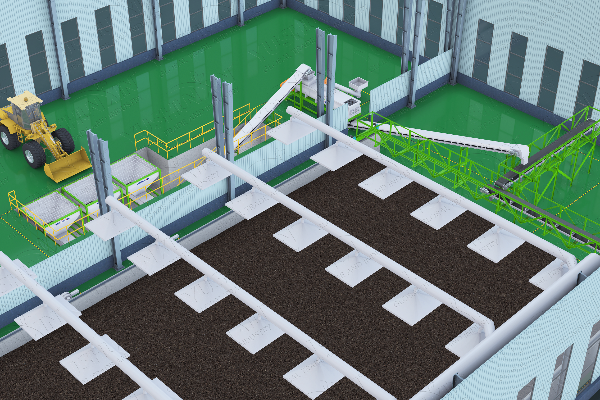

Granular Carcoal-based biofertilizer production process

We have three methods of biochar bio fertilizer pelletizing, it includes:

Addition of microbial inoculate to the granulation

Firstly, you should crush the biochar fertilizer materials, and then add microbial inoculate to the carcoal-based fertilizer material. Next, you should put it into the mixer together to mix it fully. So I recommend that you choose the double shaft mixer of our company. It has high efficiency and large capacity.

Lastly, you can sent them to granulate, dryer, cooler and package it.

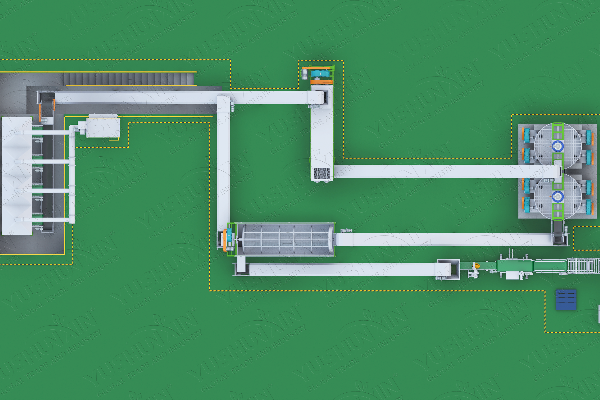

Addition of microbial inoculate during granulation

If you want to make bio fertilizer granule from biochar easier and faster, you can choose addition of microbial inoculate to the granulation.

First of all, mix the organic material and biochar, then add the fungus according in a certain amount. Then sent them together into the granulator to add bacteria and pelletize. Finally, the product can be made after drying, cooling and packaging.

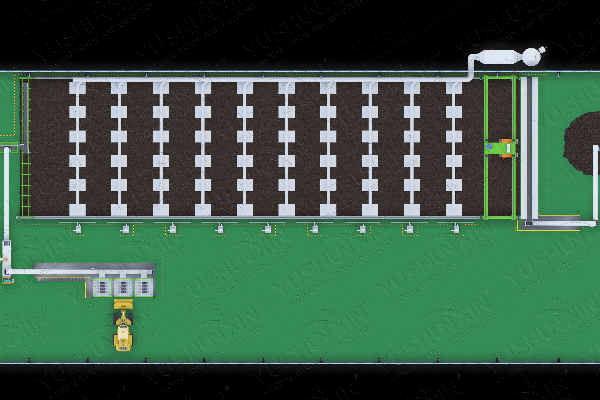

Addition of microbial inoculate after granulation

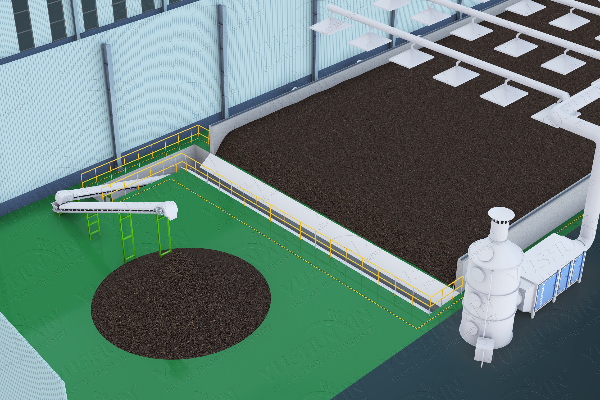

If you want to keep the nutrients inside the biochar bio fertilizer, then you can option for addition of microbial inoculate after granulation.

Adding microbial inoculate after drying can effectively prevent the high temperature from killing microbial bacteria, so that the microbial bacteria are fully retained.

First, the organic material and carbon powder are mixed and fed together into the granulator for pelletizing. Then after drying, the microbial inoculate is sprayed with coating machine and finally packed.

So we recommend you to use the coating machine. It can spray the microbial inoculate to the carbon-based biofertilizer, and it has a favorable price, for details you can contact our sales staff.

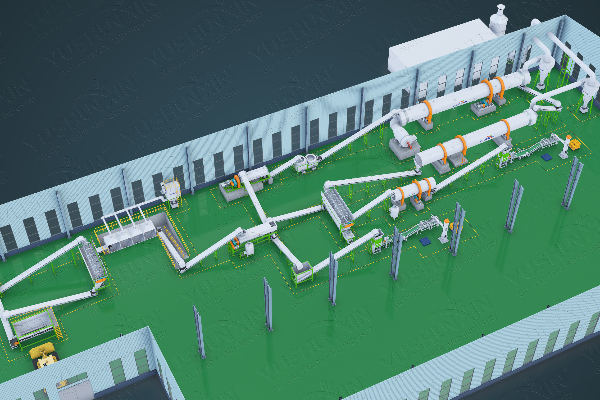

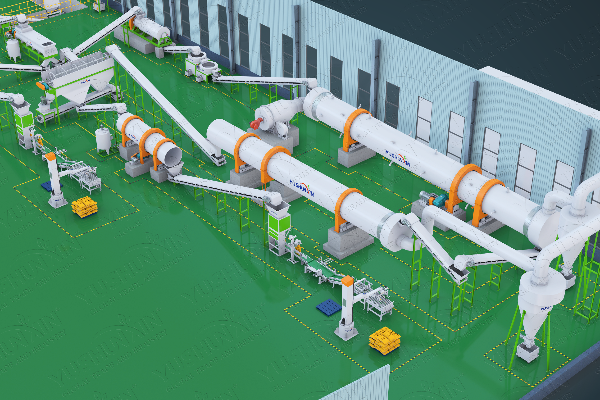

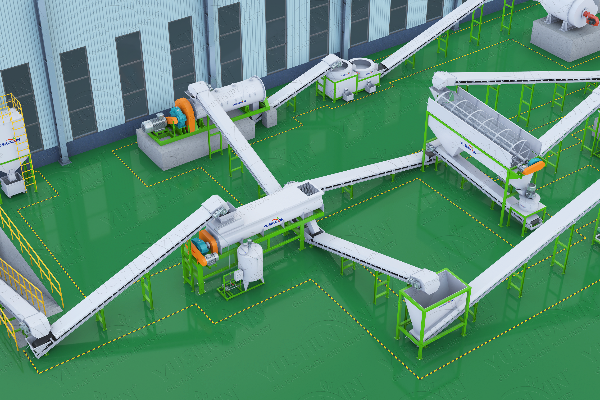

What equipment is used to granulate biochar bio fertilizer

Biochar bio fertilizer product granulation is divided into wet granulation method and dry granulation method. And it uses different process equipment.

For the wet granulation method, there is a disc granulator machine. And for the extrusion method, there are double roller extrusion and flat die machines. All of them can rapid make carbon-based bio fertilizer from biochar.

How much budget do you make bio fertilizer

We have two production lines, one is for powder and the other is for granules, and the price is different depending on the production line.

What are the benefits of microbial fertilizers?

Why choose our company's equipment ?

If you want to make bio fertilizer from biochar, you need to choose a reliable company. So, you can consider our factory. I can tell you from three aspects.