What is horizon fermentation tank?

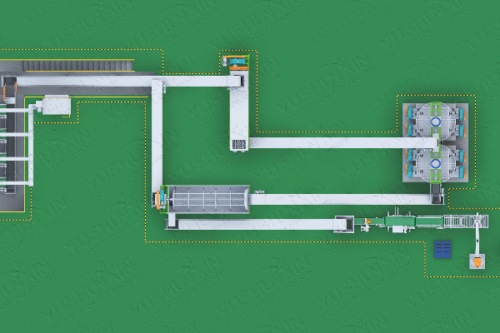

Horizontal Fermentation Tank in our factory – the ideal equipment for composting and fermentation of biochar-based materials.This tank is designed to provide a controlled environment for the decomposition of carbon-based fertilizer materials. Such as crop straw, rice hulls, corn stalks etc. With its large capacity and efficient system, our horizontal fermentation tank can process large volumes of material quickly and effectively. Built with high-quality materials and advanced technology, our fermentation tank is designed for long-lasting durability and reliable performance.

Why fermentation is important for charcoal-based fertilizers

The principle of horizontal fermentation cylinder

The poultry manure, wheat straw, proteins, microorganisms in horizontal fermenter. And fermentation cylinder has a certain temperature, humidity and sufficient oxygen. So, Microorganism to manure in the organic matter, proteins as food, rapid breeding.

What the process of composting?

When y0u are going to compost, materials will consume organic matter, protein and oxygen in the carbon-based fertilizer. And it produces ammonia, CO2 and water vapor. At the same time, it releases a large amount of heat. So that the temperature inside the organic fertilizer fermenter tank rises. At 45 ℃ ~ 60 ℃ to promote microbial growth and metabolism. At 60 ℃ or more can kill harmful substances in the garden waste. It balance the survival of the beneficial bacteria temperature, humidity and PH value to meet the conditions for the survival of beneficial bacteria.

How the horizontal fermentation tank work?

when manure fermented in the fermentation tank, the temperature sensor will real-time monitoring the tank inside temperature, and to regulating the temperature by starting on the industrial electric blanket (embedded in the two-layer tank wall), to make sure the best living temperature (60-70℃) for beneficial bacteria.

And in the upper side of the fermentation tank, the heating device will also be heating the oxygen that is pressured into the tank to make sure the fermentation tank has suitable temperature.Besides, the heated oxygen will be pressured into the tank by high pressure Roots blower to make sure the aerobic bacteria has enough oxygen. Tank inside oxygen concentration also monitoring by the oxygen sensor.

Advantages of horizontal fermentation cylinder

Improving fertilizer quality

If you want to make biochar-based fertilizer is fermented by fermentation tank, and it has rich nutrient ingredient. Besides, it also has high stability. So it can significant improve the quality and output of carbon-based fertilizer, furthermore, it can improve your interests.

Resource utilization

Through the organic fertilizer fermenter, the waste can be converted into carbon-based fertilizer. And realizing the effective use of resources. At the same time, it can protect the environment, reducing the pollution of the land. What’s more, it can protecte the health of the workers.

Wide range of applicability

Organic fertilizer vertical fermenter is suitable for the fermentation of many kinds of charcoal-based fertilizer raw materials. Such as livestock and poultry manure, plant straw, rice hulls, garden waste and so on. So, it has a wide range of applicability.

High level of automation

Horizontal fermenter for charcoal-based fertilizer adopts automatic control. And this is our company’s advanced equipment, so it can complete work in time and reduces the manual operation. Besides, it greatly reduces the time. At the same time, reduces the labor intensity and improves the production efficiency.

Environmentally friendly and energy efficient

The fermentation temperature can reach 80 degree-100 degree. It can thoroughly kill the eggs of pests and harmful germs. What’s more, Organic fermentation tank environmental pollution-free, and low energy consumption. The waste gas and wastewater emissions of the equipment are in line with national environmental standards.

Saving space

The equipment adopts horizontal design. It saves the use of land area. If you don’t have enough space, then this equipment will be your best choice. Horizontal fermentation tank not only can help you to fermented but can save your factory space, eliminate your trouble.

Why you need to buy a fermentation tank?

Biochar-based fertilizer has been history for hundreds of years. The initial fermentation is a no-additive fermentation, which is a natural fermentation. Natural composting costs are low, but it very slow, even lack of effectiveness, and not fully fermented. Besides, secondary fermentation after fertilizer application. Severe cases even cause crops to wilt, which causing unnecessary economic loss. What’s more, the general charcoal-based fertilizer production method is inefficient and cannot meet the current demand for fertilizers. Now our ShunXin company produces the fermenter, which can improve the production efficiency.This will achieve its harmlessness, so obtain environmentally friendly organic fertilizer, to solve the problem of environmental pollution of garden waste. High-temperature aerobic fermentation can also harmlessly treat them into charcoal-based fertilizer, turning waste into treasure. Ensure sustainable development.

Why do you choose us company?

Our company is the leading brand of fertilizer equipment in China. The company is an environmentally friendly high-tech enterprise specializing in the research and manufacture of biochar-based fertilizer. Besides, our company was established in 2005. And has introduced internationally advanced large and medium-sized refined carbon-based fertilizer machine. What’s more, the price of our company about $150,000.00. We are also an enterprise, which self-operated import and export. What’s more, our company has a advanced team, whose are dedicated to the research and development. So, you can relief if you choose our factory to buy equipment.