Top 3 biochar fertilizer making line in 2023

In 2023, our company has selected top 3 biochar fertilizer making line. They are disc granulation production line, double roller extrusion granulation production line and powdery organic fertilizer production line. They are all loved by customers, and I’ll go over them one by one below.

Advantages of powder organic fertilizer production line

A customer who comes from India, he told us he wants to buy some biochar fertilizer machine. And his biochar fertilizer machine budget is in $50,000, he wants to know if we can recommend our products for him. We asked him what fertilizer production line he needs, he said he went to a granulation production line. And the first is the powdered organic fertilizer production line. This pelletizing line has a number of advantages.

Advantages of powder organic fertilizer production line

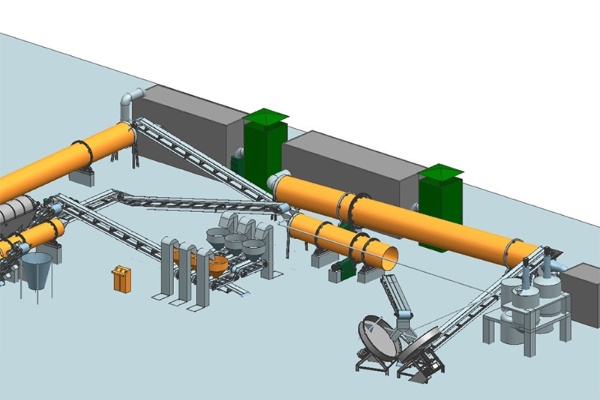

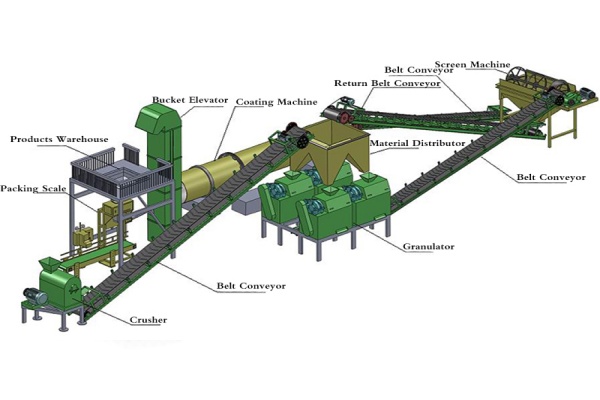

The second line is a disc granulation production line, which is a granular fertilizer production line. Besides, it is most popular fertilizer production line in top 3 biochar fertilizer making line. And Its process includes fermentation, crushing, mixing, granulation, drying, cooling, sieving, packaging. The difference between disc granulation production line and roller extrusion granulation production line lies in the use of different granulators.

The first advantage is that the disc pelletizer has a high establishment rate. Because it adopts the whole structure, so it affected by the centrifugal force, and the machine is also a certain angle of inclination, so it can be more than 95% of the granulation rate.

The second advantage is its high production efficiency. Because the pelletizing tray equipped with three discharging ports. It is convenient for intermittent production operations, greatly reducing labor intensity, reducing the number of workers, and also improving the production efficiency.

The third advantage is its long service life. Adopting flexible belt transmission, smooth starting, slowing down the impact and improving the service life of the equipment. What’s more, the bottom of pelletizing plate strengthened by many steel plates, never deformed. It also has aggravated, thickened and solid base design for smooth operation.