If you add biochar into organic fertilizer, the advantages includes maintains soil moisture and promotes plant growth. So many organic fertilizer producers recognize the importance of biochar organic fertilizer.

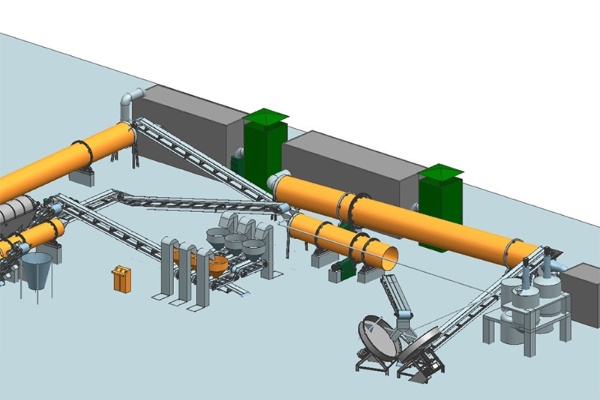

The process of biochar organic fertilizer making roughly including : composting, mixing, crushing, granulating, screening, drying, cooling and packaging. And the most important thing is you should have machines to help complete biochar organic fertilizer production. So, you should choose a reliable biochar organic manufacturer.

What types of biochar organic fertilizer making?

If you need to make biochar organic fertilizer, then we recommend you two kinds of organic fertilizer production lines.

The powder production line

The process of powder production line is simple compared with granulation production line. It is includes collect materials, composting, mixing, crushing, granulating, screening and packaging.

Collect raw materials

The first step in making biochar organic fertilizer is to collect raw materials. These raw materials can provide more nutrient for plant. Some common raw materials for organic fertilizer manufacturing include:

- Animal manure:poultry manure, chicken dung, pig manure, etc.

- Agricultural waste: straw, soybean meal, cotton meal, etc.

- Industrial waste: wine lees, vinegar lees, tapioca residue.

- Urban sludge: such as river sludge, sewer sludge, etc.

Adjustment of moisture

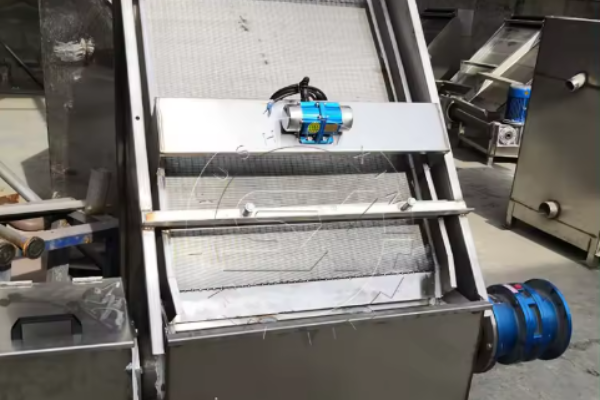

The second step is process the raw materials. For example, the chicken manure or cow manure need to dry and reduce the watery content. Because there is too much water in fertilizer to compost. So, you must adjustment of moisture. what’s more, it is important for compost. So we recommend squinting dehydrator for you. The capacity is 10-15m3/h. And the speed is 48r/min.

Composting materials

Aerobic compost can kills disease, insect eggs and weed seeds. More importantly, composting produces beneficial humus that can improve soil fertility. So We recommend some compost machines for you. If you want to produce small biochar fertilizer production line, then we can recommend groove compost machine and self-working compost machine. On the contrary, if you willing to produce large biochar organic fertilizer, we will recommend horizontal pot or wheel type compost machine. In addition, the price of our machines are favorable.

Crushing materials

Crushing is important process in making biochar organic fertilizer. It can grind the large materials which missed in composting, so that better to compost. So, we recommend the new type vertical crusher for you. It use steel materials, and without screen cloth , so for high moisture material, it not easy to block. Furthermore, the material discharging is smooth. And the price is very favorable, which about $2,000- $5,000. And the capacity is large, it can reach 3-15 kg/h.

Mixing the materials

Then you can mix the processed materials together. In the process of producing organic fertilizer, it is necessary to configure mixer equipment for mixing various fertilizers. So as to ensure uniform mixing and reliable quality. If you want to mix more efficiency, then we recommend double shaft mixer for you. If you want to produce large capacity, then we recommend horizontal mixer for you .The budget is very economic for both machines.

Screening and packaging

The final process is screening and bagging your processed organic fertilizer. Generally speaking, you need to remove large pieces of compost or impurities. So, you should screening. So er recommend rotary screening machine. And the last process is packaging. If you need to sell your biochar organic fertilizer then you should bagging it. So that can transport and stored. We have two kinds of packaging machine to recommend to you. One is the packing machine for powdered organic fertilizer and the other is the bagging machine for granular organic fertilizer.

What advantages for you to use our machine?

In organic fertilizer manufacturing, if you use our compost turner machine will has many advantages. For example:

How to determine composting success

- 1

Appearance: When the compost is mature, the color will change to dark brown or black without any smell.

- 2

Moisture: Mature compost has moderate moisture, not dry or wet.

- 3

Temperature: The temperature of mature compost will gradually decrease to the same temperature as the surrounding environment.