Six steps to make charcoal-based fertilizer from chicken manure

Pretreatment the chicken dung and biochar:

The first step you need to dewater the material. Chicken manure contains a lot of moisture. But you need to keep the moisture at about 60%. By this way, we recommend you our company’s two kinds dehydrator machine. One is suitable for large capacity, the other is suitable for small capacity.

Compost the chicken manure and carbon materials:

In order to kill insect eggs and harmful bacteria in fertilizers, you need to compost. Because high temperatures kill them. You should to stack the chicken manure and carbon in the compost pile. Besides, you need a compost turner machine to turn them regularly.

Crushing the chicken manure and biochar materials:

After composting, you need to crush the chicken manure and carbon materials, so that you can better pelletizing.

We recommend you new type organic fertilizer crusher. Because it can easily pulverize chicken manure and carbon matrials.

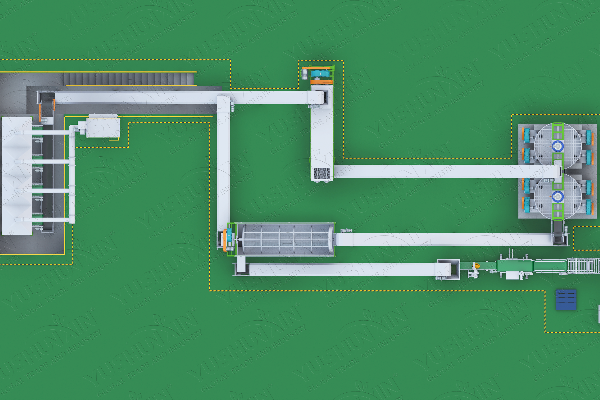

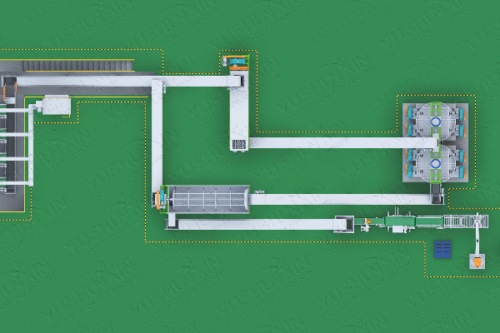

Technology for making chicken manure and biochar fertilizer

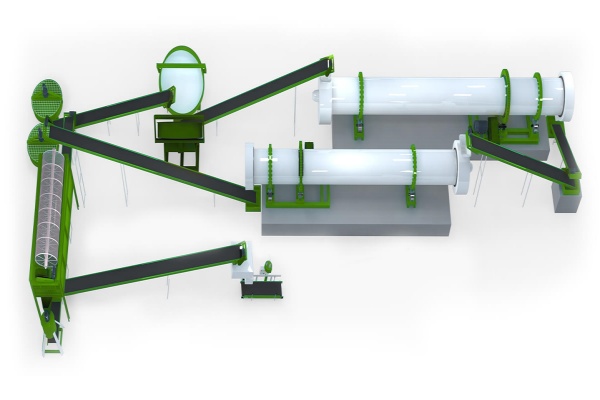

In granulate process of making chicken manure biochar fertilizer, we have dry granulation and wet granulation.

The benefits of use equipment of Yu Shun Xin

If you want to biochar fertilizer from chicken dung, you need to choose a reliable company. So, you can consider our factory. I can tell you from four aspects.