What are the steps for mixing cow dung and carbon as fertilizer together?

Cow dung and carbon as fertilizer is a way of converting traditional agricultural wastes into efficient fertilizers. It has far-reaching significance in promoting sustainable agricultural development. The following are the production steps of cow dung fertilizer.

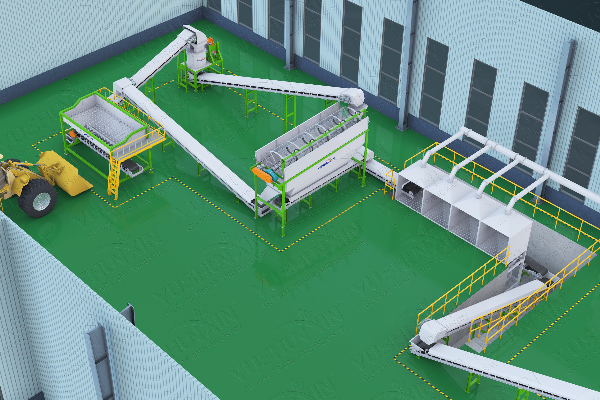

First, you need to collect cow dung but make sure that the raw material is fresh and uncontaminated. This helps to produce high quality carbon based fertilizer. Then, if you want the fermentation to be faster, then you can use our fertilizer mills. Our company has a wide range of compost grinders for sale, such as new vertical grinders and chain grinders to crush larger chunks. In addition, the moisture content of the cow manure must be adjusted to suit the pelletizing process. Cow manure has an original moisture content of 80%, which can be maintained at 30% to 40% when you use our cow manure dehydrator. This is the ideal moisture content for composting cow manure.

First, to fully mix your cow manure with carbon. You can use our factory’s professional charcoal-based fertilizer mixer to mix the crushed cow manure with carbon. Then the mixed carbon and cow manure will be piled together for aerobic fermentation. This stage is crucial for eliminating harmful microorganisms and destroying insect eggs. Also, make sure that you turn the compost frequently to aerate it. This is because oxygen stimulates the activity of microorganisms and promotes the rapid completion of the composting process. Besides, you can also use our biochar fermentation machine.

How much does a cow dung and carbon as fertilizer production line cost?

What other equipment would be needed to make fertilizer from pelletized cow manure and carbon?

If you need to make charcoal based fertilizer pellets and need cow dung and carbon as fertilizer, then you also need charcoal based fertilizer pelletizer machine. We recommend you two kinds of machines, one is large carbon based fertilizer rotary granulator machine and the other is carbon based fertilizer disc granulator machine.

our charcoal based fertilizer rotary drum granulator has a capacity of 2-20 tons, if you are a large capacity charcoal based fertilizer production line, then you can consider this machine. If you have a small production, then you can consider our disc pelletizer equipment. It has a capacity of 0.5 tons to 6 tons. And it has high granulation rate, which can reach 95%.